STELLENANGEBOTE

Wir halten Sie immer am laufenden mit den aktuellesten Stellenangeboten!

Aktuelle Artikel

Tube Düsseldorf 2024

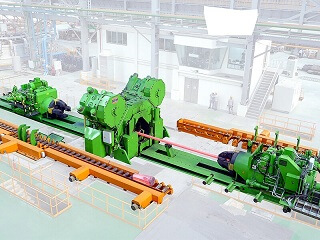

Wir freuen uns, Sie auf der Tube in Düsseldorf begrüßen zu dürfen! Als Aussteller sind wir vom 15. bis 19.04.2024 auf der Nr. 1 Fachmesse der Rohrindustrie vertreten.

Besuchen Sie uns gerne an unserem Messestand G03 in Halle 04.

Energieaudit Energieeffizienz

Die GFM GmbH in Steyr wurde als ‚Klimafreundliches Unternehmen‚ ausgezeichnet. Die Auszeichnung zeigt, dass die GFM einen wesentlichen Beitrag zum Klimaschutz und zur nachhaltigen Steigerung der Energieeffizienz leistet.

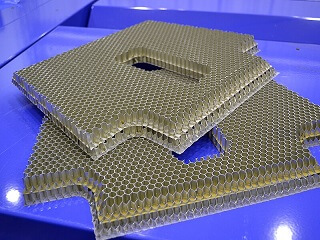

JEC World Paris 2024

Vom 5. bis 7.03.2024 sind wir als Aussteller auf der JEC WORLD in Paris, der weltgrößten Fachmesse für faserverstärkte Kunststoffe, vertreten. Wir freuen uns auf Ihren Besuch auf unserem Messestand M99 in Halle 5.

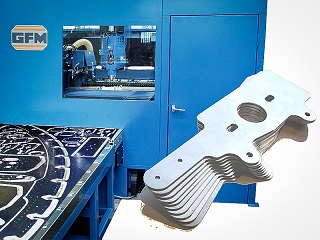

GFM Maschinen & Produkte

Radialschmiedemaschinen / Umformen

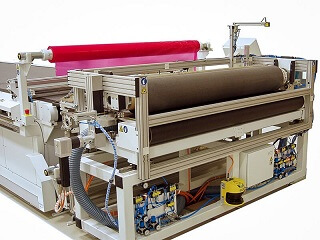

Schneiden / Profilieren / Automatisierung

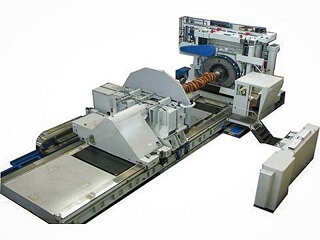

Fräsmaschinen für Kurbelwellen